Loading

area design

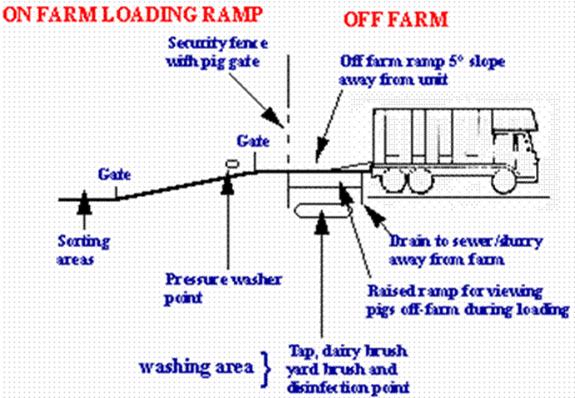

The following may be

considered when designing a loading area for pigs

|

Pigs |

|||

|

|

Any pig transported must be fit to load onto the truck and unload at

the arrival point |

||

|

Moving pigs |

|||

|

|

Pigs

can be moved by a stockman’s voice; hands and gestures; boards; flags or

paddles |

||

|

The pigs are not to

be hit by any of these moving aids |

|||

|

Electric prodders are not to be

used to move pigs |

|||

|

Pigs move easier

when the stockperson has fully planned the move |

|||

|

Basic design |

|||

|

|

The loading area

should have no sharp turns |

||

|

The loading area

should be free of any protrusions – such as nails or bolts |

|||

|

There should be no

steps or gaps in the walkway |

|||

|

Ideally there should be no slope to the loading area |

|||

|

If a slope is

necessary, the maximum slope should be 20° |

|||

|

The ramp for

finishing pigs should be 0.9 to 1.0 m wide – sufficient for two bacon pigs |

|||

|

Have a see through

fence down the middle of the ramp – so the pigs can see each other |

|||

|

The ramp sides

should be smooth, solid and 1 m high |

|||

|

The loading area

should be well lit – 250 lux |

|||

|

Avoid any sharp

contrast in shade and hue. This

includes wet patches. |

|||

|

The loading area

should protect the pigs and staff from the weather – heat and cold |

|||

|

The ramp should have

a walkway for staff |

|||

|

There should be a

flat area 2 meters long at the top of the ramp |

|||

|

A biosecurity creep

bar should be placed at the top of the ramp |

|||

|

Do not allow the

farm staff to enter the truck |

|||

|

Do not allow the

truck driver to enter the ramp area |

|||

|

Cleats in the ramp

should be 2.5 cm metal rod separated by a gap more than the pig’s feet but

not wide enough to allow the pig to slip |

|||

|

|

|||

|

|

|||

|

Trucking Basics |

Space

allowance

|

Average live weight (kg) |

Space allowance (m2/head) |

|

|

50 |

0.22 |

Reduce

stocking density by 10% in hot weather – greater than 25° C Avoid

transporting pigs in very hot weather –

greater than 30°C |

|

75 |

0.29 |

|

|

100 |

0.35 |

|

|

125 |

0.42 |

|

|

150 |

0.48 |

|

|

175 |

0.55 |

|

|

200 |

0.61 |

|

|

225 |

0.68 |

|

|

250 |

0.74 |

|

|

275 |

0.81 |

|

|

300 |

0.87 |

|

Loading ramp rules- Biosecurity and Cleaning |

|

|

1 |

Trucks must have no pigs on board, must be clean, washed and disinfected |

|

2 |

The off-farm disinfectant/washing area (see above) must be prepared prior to each loading by the unit staff, (wearing off-unit clothing) and then they must re-enter the farm |

|

3 |

The truck driver must not own or farm pigs |

|

4 |

The truck driver must inform a member of staff using the klaxon/horn upon arrival |

|

5 |

The truck drivers must wash their hands and wear the over-boots provided and dip the boots in the disinfectant provided |

|

6 |

The truck driver's name and vehicle number should be logged in the animal movement book |

|

7 |

Farm staff must not cross the security fence line or the loading ramp |

|

8 |

The loading ramp area must be thoroughly cleaned after loading each batch of pigs |

|

9 |

The truck driver must not enter the unit, under the security fencing onto the on-farm ramp, to assist the loading |

|

10 |

All entry and exit points should be well lit, ideally with proximity sensors |

|

11 |

The sorting area and on-farm loading area must be thoroughly cleaned and disinfected once the pigs have arrived or left |